Color Coded Light Metering

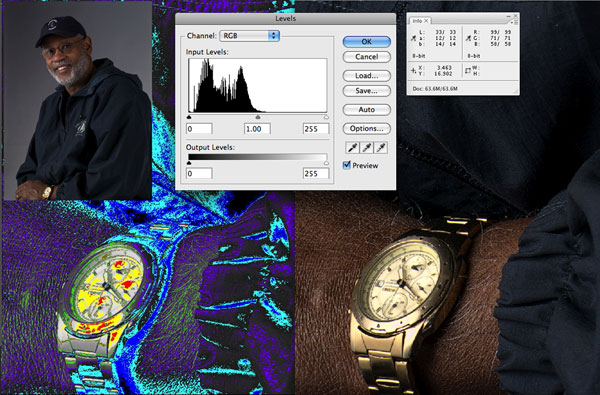

MegaVision conceived and implemented Color Coded Light Metering in the earliest days of digital capture, designing a color coded gamut alarm image overlay to tag out-of-range densities in the picture file, relative to the paper's ability to render density. That was a lot of function then, and it's just as valid today. Prior to linearized monitor displays, reliable input and output profiles, and hi-bit imaging, a method of getting pictures that printed properly was needed for digital capture to be taken seriously. Given the state of the tools of the day, evaluating the target was the prudent approach; become familiar with what the target likes best, and make only that. Shooting specifically what the target needs is the best path to printing a photographic vision on paper, or on any target. Color Coded Light Metering is customizable for any target. If a paper can reliably separate detail to 94%, any pixels in the picture darker than 94% are color coded dark blue to indicate they will not be separable on the paper. If the shooter wants darker than 94% to render with separable detail, it's a simple matter to add some fill light, until the area of interest is no longer dark blue in the Color Coded Light Meter. Low values that would barely print with detail are coded in light blue, so the shooter can see the transition from black to just discernible. Highlights are treated in the same fashion by using yellow to denote density that is barely discernible, and red to denote areas of the picture that will print as featureless white on the target paper. A typical Color Coded Light Meter approach is to expose for the target's highlight, and fill for the shadow. Additional colors in the Meter function add important areas of interest to the shooter; mid-tone, quarter-tone, and three quarter-tone. Colors can be selected so that portrait ratios can be loaded-- a shooter can load a 2:1 ratio for example, and use it to simplify setting up a lighting scenario.

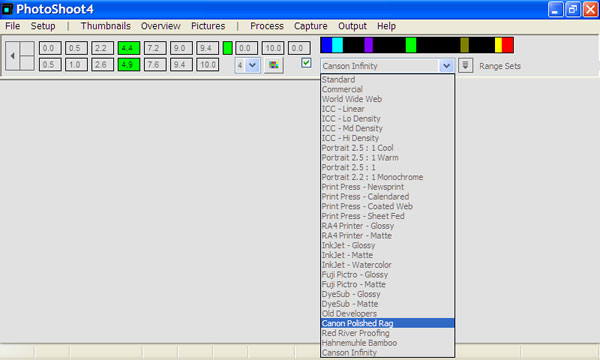

Color Coded Light Metering is loaded from known, observed behavior of the target. Sending a file called a Target Characterizer containing a labeled gradient to the target will allow the naked eye to see the highest and lowest separable values on that target, using any printer and any inks. Programming the target's observed endpoints into the Color Coded Light Meter is simple and the user can program and name the meter accordingly and save it for easy recall.

A histogram report can be misleading - the photographer can't identify the paper's highest and lowest separable values in the histogram's data stacks and yet MegaVision's Color Coded Light Metering indicates a perfect exposure.

Where many suggest high bit workflows, third party .dng converters, and special viewing environments, MegaVision crafts pictures with light. MegaVision has other workflow options, but Color Coded Light Metering provides the perfect start for making pictures. Instead of resorting to the Photoshop® or Lightroom® edit-of-the-month, the photographer can use light to create a uniquely personal image. Color Coded Light Metering is the intelligent tool for the advanced lighting technician. |